- New

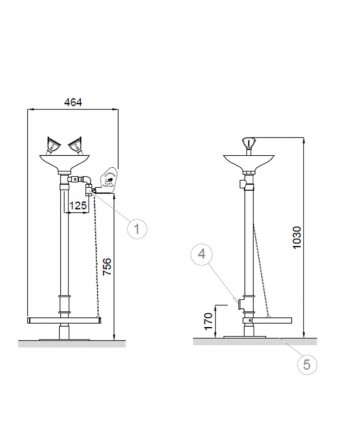

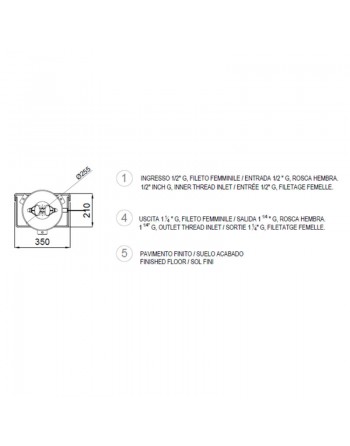

Emergency eye washes NOFER or equivalent, high flow rate to low pressure with total flow control valve, automatic instantaneous opening and manual closing by automatic lever and pedal. Body constructed in galvanized steel with epoxy paint coating, green color, and polypropylene collection cup, also green in color.

Complies with standards: ANSI Z358.1-2019 and EN 15372.

This is designed to provide a smooth and continuous flow of water to rinse out hazardous contaminants from the eyes, thereby reducing the risk of permanent damage.

Recommended uses: Laboratories. Industrial installations. Mechanical workshops. Construction areas. Pools. School laboratories